Мы изготавливаем продукцию по индивидуальному заказу

70 % нашей продукции изготавливается по индивидуальному заказу, т. е. с высокой степенью персонализации

в ответ на конкретные пожелания и потребности наших клиентов.

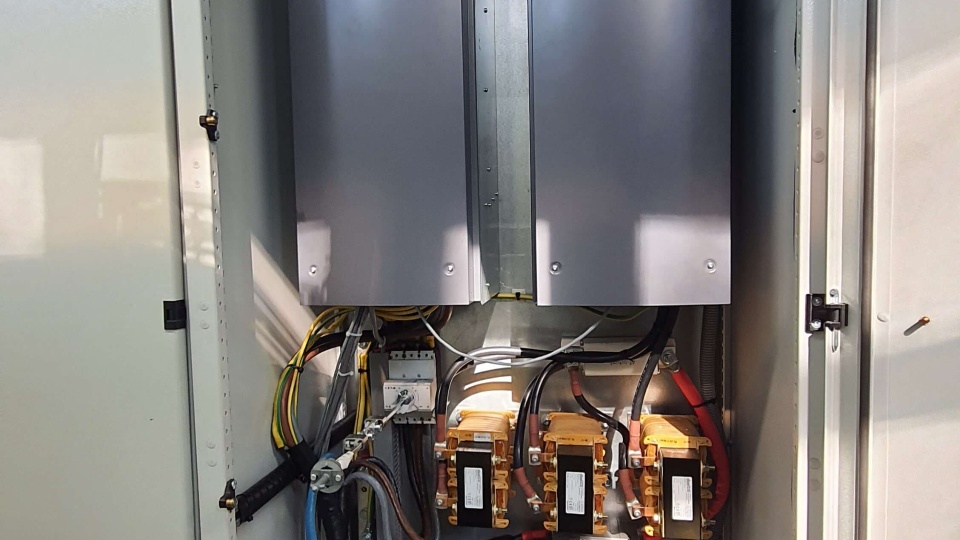

Compensation reactor ED3K IP34

Weatherproof, effective heat dissipation.

- Клиент ONDE

- Отрасль Возобновляемые источники энергии

- Категория Дроссели

- Дата Апрель 10, 2025

Client:

ONDE is one of the leading renewable energy (RES) companies in Poland, operating as a general contractor and developer of large-scale wind and solar farms. The company delivers projects comprehensively – from concept and construction to maintenance. ONDE has completed over 400 wind and photovoltaic farms with a total capacity of nearly 5 GW, actively supporting the country’s energy transition. Its portfolio of RES development projects exceeds 1.3 GW.

Challenge:

ONDE required a compensation reactor in an outdoor enclosure, designed for operation in field conditions on a photovoltaic farm. Due to the cyclic nature of PV system operation, compensation reactors are particularly exposed to harsh environmental conditions. They do not operate continuously – they are activated primarily during periods without sunlight, which increases the risk of water vapor condensation inside the enclosure.

The enclosure design had to ensure both effective heat dissipation and protection of the reactor windings against atmospheric factors such as rain and snow.

Solution:

For ONDE, we supplied two ED3K compensation reactors – 545 kVar and 345 kVar. To ensure failure-free operationin a demanding environment, we enclosed them in ELHAND IP34 durable enclosure, equipped with:

- Ventilation grilles with water protection – minimizing moisture and rain infiltration.

- Rodent protection mesh – preventing rodents from entering the interior.

- Anti-condensation heater – eliminating the risk of moisture buildup and corrosion.

- Transport handles – facilitating easy transport and installation.

Results:

The compensation reactors in the Elhand IP34 outdoor enclosure have significantly improved the efficiency of ONDE's photovoltaic farm.

- Reactive power balancing – the supplied inductive reactive power compensates for excess capacitive reactive power, stabilizing voltage.

- Stable voltage – improved energy quality ensures safer and more efficient system operation.

- Lower energy losses – better reactive power compensation increases the efficiency of the PV system.

- Failure-free operation in harsh conditions – thanks to the weatherresistant IP34 enclosure.

- Quick installation – no civil works required.

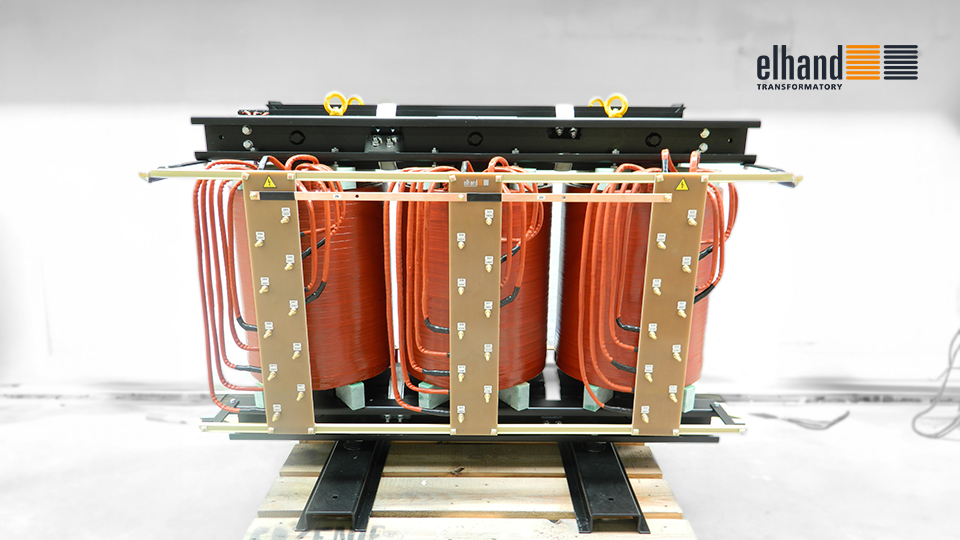

Excitation Transformers 74 kVA

High reliability, optimal operating parameters, resistance to higher harmonics.

- Клиент The Institute of Power Engineering

- Отрасль

Силовая электроника,

Возобновляемые источники энергии - Категория Трансформаторы

- Дата Ноябрь 20, 2024

Client:

The Institute of Power Engineering - National Research Institute, Gdańsk Division is a leading research organization specializing in analyzing and implementing innovative solutions in automation for the power sector. It actively operates in the fields of power generation from both conventional and renewable energy sources (RES), as well as in energy storage, transmission, distribution, and efficient utilization. Among its five divisions, the Gdańsk branch stands out as the largest and most prominent field office, playing a key role in executing strategic projects.

Challenge:

A sugar refinery, acting as the end investor, required a reliable and modern excitation system for its synchronous generator. The turbine-generator set was to play an important role in reactive power compensation and ensuring emergency power supply in the event of a loss of access to the mediumvoltage network.

The greatest challenge was meeting the tight deadline for transformer delivery before the start of the so-called sugar campaign, which runs from autumn to mid-winter. During this time, any failure could interrupt production processes. The excitation system needed to be overloadresistant and ensure stable operation of synchronous machines.

Solution:

Elhand provided two advanced transformers for the excitation circuit of the synchronous generator, as part of a modernization effort led by the Institute of Power Engineering, Gdańsk Division. Elhand's transformers were designed with a focus on:

- High reliability – critical for the plant's operation.

- Optimal operating parameters – ensuring stability in both static and dynamic states.

- Resistance to higher harmonics – present in the circuit, mitigating the risk of overvoltage, overheating, and system instability.

The voltage regulators used in the generators feature excellent regulation characteristics and precise voltage parameter adjustment, enhancing the efficiency and safety of the entire system.

Results:

The excitation transformers delivered by Elhand:

- Operate faultlessly within a system equipped with an automatic voltage regulator, adapting voltage to the requirements of power electronics.

- Have been optimized for resistance to current harmonics, preventing issues such as overvoltage and overheating.

- Ensure stability and reliability, which are crucial for maintaining continuous production processes during the sugar campaign.

The outcomes of this collaboration confirm the effectiveness of Elhand's technology in demanding industrial applications.

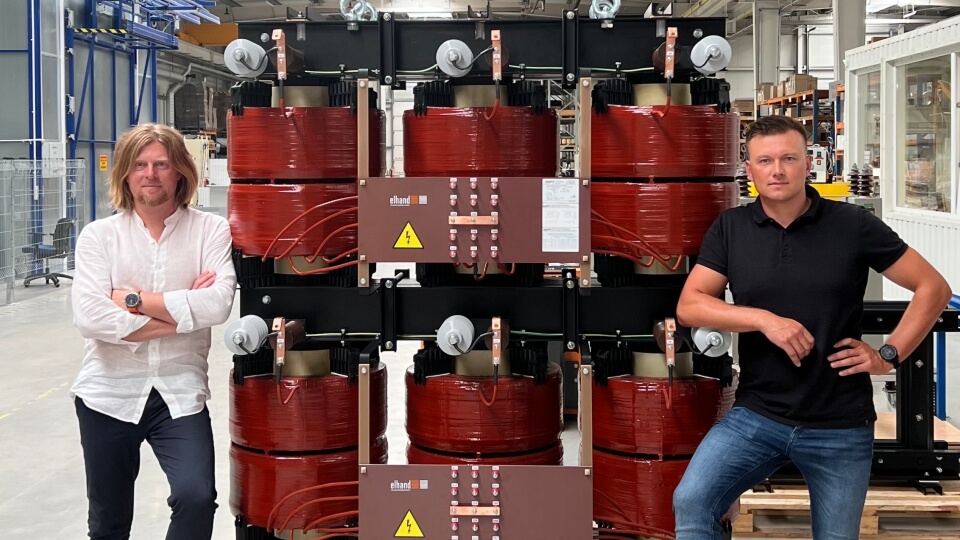

Isolation Transformer 1250 kVA

Flexibility in design and customization by engineers to meet the requirements of building a bidirectional AC/DC converter with integration into the medium voltage network.

- Клиент ZPUE S.A.

- Отрасль Возобновляемые источники энергии

- Категория Трансформаторы

- Дата Май 20, 2024

Client:

ZPUE S.A. is a recognized leader in the power and industrial sectors, having specialized for 35 years in the creation of advanced solutions for the power industry, such as container transformer stations, pole-mounted transformer stations, MV and LV switchgears, energy storage, and fast charging stations for electric vehicles.

Challenge:

To maintain independence of power supply from the distribution grid and increase the efficiency of energy produced by the 1.3 MWp photovoltaic power plant, the Client decided to build a 1 MW energy storage facility with a capacity of 4.3 MWh.

The purpose of the energy storage facility is to store excess produced on sunny days and discharge it during times of increased demand by consumers and participate in electricity trading. Additionally, the energy storage will act as a power; in the event of a power failure on the distribution grid, it will form a micro-grid together with the PV system (off-grid operation of the storage).

The energy storage is built from an energy storage unit and a bidirectio-nal AC/DC converter withconnection to medium voltage grid. One of the key components of the converter is the 15.75/0.39 kV isolation transformer, which integrates the grid system and output voltage from the IGBT converter.

Solution:

The ET3H 1250KVA 15.75/0.39 kV isolation transformer produced by Elhand was selected due to its flexibility in design and customization by engineers to meet the requirements of building a bidirectional AC/DC converter with integration into the medium voltage network. Additionally, the transformer's technology enables energy transmission in both directions, maintaining high energy efficiency even with rapidly changing loads.

EEffects:

The use of the Elhand 125KVA transformer enabled the achievement of the following goals:

- Increase in the share of renewable energy sources (RES) – better utilization of energy from renewable sources to power the Client’s facilities.

- Energy independence – enhancement of the Client’s facility’s energy independence.

- Increased network stability – due to the ability to quickly respond to changes in energy demand and production.

- Reduction of energy losses – optimization of energy flow and utilization throughout the entire infrastructure.

„We have been collaborating with Elhand for almost 20 years. In this project, Elhand has once again proven to be a reliable supplier we can count on. In our mutual relationship, we value the speed of service, excellent technical support, and the ability to customize transformer designs to meet our needs. We are pleased to create pioneering solutions for the Polish power industry together, such as energy storage systems.” - Project Engineer | New Technologies Department | ZPUE

DC Reactors

Seamless control of the PP1 pump.

- Клиент JMS Automation

- Отрасль Силовая электроника

- Категория Дроссели

- Дата Май 13, 2024

Client:

JMS manufactures, sells and services industrial automation systems. The company is an authorized partner of Danfoss Drives Poland. JMS offers professional service of VLT and VACON drives.

The Challenge:

The RADPEC district heating plant in Radom required a fail-proof backup system for a critical 75kW water pump. Continuity of the pump's operation is essential for maintaining heating supply to the city, making it imperative that the system would withstand power outages without affecting performance.

The Solution:

Elhand supplied DC reactors for an intermediate circuit between a Danfoss DC-DC converter and a battery energy storage unit, executed by JMS. The DC backup system ensures continuous, uninterrupted operation, crucial for the plant's operation.

The Results:

JMS designed a 75kW pump control system using VACON (Danfoss Drives) frequency inverters and Elhand's DC reactors, offering seamless control of the PP1 pump with 400VAC supply and ensuring operation for at least 15 minutes during power outage. The system, featuring an uninterruptible switch from mains to a VRLA-type AGM battery supply, maintains pump performance and recharges batteries during normal operation. The AGM batteries have a lifespan of 10-12 years.

„The Elhand ED1X-1mH/92A 750V reactor is distinguished by its precision engineering, ensuring that the DC-DC conversion process operates within the desired parameters and significantly contributed to the success of our project. This experience with Elhand not only showcases their capability to provide solutions that meet unique demands of drive systems but also cements their reputation as a reliable and trustworthy partner." - Janusz Mamla | JMS Automation

MV Transformer

Stable and strong power source.

- Клиент Geotermia Koło

- Отрасль Горнодобывающая отрасль

- Категория Трансформаторы

- Дата Январь 22, 2024

Client:

Geotermia Koło Geotermia Koło is a dynamically developing company that plays a crucial role in providing sustainable energy to the residents of Koło. The activities of Geotermia Koło focus on utilizing geothermal heat sources to provide a sustainable and ecological source of heat for the residents, offering a modern and environmentally friendly solution in the field of district heating.

The Challenge:

The challenge was to ensure efficient and reliable power supply for a deep well water pump, a key component of the geothermal system. The pump, with a power of 420kW and suspended at a depth of 350 meters below the ground level, required a stable and strong source of electricity for effective operation.

The Solution:

Specializing in electrical power solutions, we provided an ET3H-610 type transformer. This specialized transformer was designed to meet the high demands of the geothermal installation, providing reliable and efficient power supply for the deep well water pump.

The Results:

The application of the ET3H-610 transformer:

- Enabled heat extraction from a deep borehole with a diameter of 10 inches and a depth of 2980 meters.

- Contributed to achieving a power of approximately 11.5MW from the geothermal installation, covering about 80% of the annual heat demand for Geotermia in Koło.

- Reduced reliance on coal-fired boilers, cutting carbon dioxide emissions by about 75%.

- The high temperature of the geothermal reservoir (around 90°C) allows for heat to be obtained exclusively from geothermal energy for a significant part of the year.

„Through collaboration, one of the most ambitious geothermal projects in Poland was successfully realized, demonstrating the possibilities of using renewable energy sources in an effective and sustainable way. This project serves as a model for other cities and regions, showing how modern technologies can contribute to reducing the carbon footprint and improving the quality of life for residents." - Przemysław Stasiak | CEO of Geotermia Koło

Ship Transformer

Short lead time during the summer period, 5 weeks.

- Клиент Telford Offshore

- Отрасль Морская отрасль

- Категория Трансформаторы

- Дата Октябрь 20, 2023

Client:

Telford Offshore is an international offshore service provider offering cost-effective construction and project management solutions to the Oil & Gas Industry. Trelford Offshore adapts to clients’ needs and operates in the most challenging environments, delivering safe access to and support of offshore worksites.

The Challenge:

We faced a significant challenge due to a short turnaround time of only 5 weeks, especially during the difficult summer season. Our task was to ensure the timely fabrication and delivery of a highquality, large marine transformer that would support the power conversion needs of the vessel, Telford 25. The transformer played a critical role in operating the motion-compensated Telescopic Gangway, facilitating safe passenger transfers from the vessel to offshore platforms.

The Solution:

Key solutions implemented included:

- Efficient Communication: We established effective communication channels to ensure a seamless flow of information, enabling real-time updates and adjustments as needed.

- Rigorous Quality Control: ELHAND experts, in collaboration with Client, maintained strict quality control measures at every stage of the transformer's fabrication. This helped us ensure that the final product met the highest industry standards.

- Accelerated Dispatch: Recognizing the critical role of the transformer, we worked diligently to expedite its dispatch, ahead of the estimated delivery date. This ensured that our client could adhere to the project schedule and mobilize the vessel as planned.

Results:

On-Schedule Mobilization: The transformer ET3SM-630 440//690 dD0 60Hz T45F AL IP23 was delivered and installed on the vessel, Telford 25, as planned. This on-time delivery allowed us to adhere to our project schedule and mobilize the vessel without delays.

Double Compensation Reactors

Very limited space for installation, possibility of its gradation 900kVAr

- Клиент Taurus-Technic Sp. z o.o.

- Отрасль Возобновляемые источники энергии

- Категория Дроссели

- Дата Август 25, 2022

Client:

Taurus-Technic Sp. z o.o.

A national leader in the field of reactive power compensation (LV and MV) and a licensed partner of SIEMENS, a world leading company in the market of electricity distribution. On the Polish market since 1991. Taurus-Technic also offers the latest solutions of LV switchgears and a whole range of MV switchgears.

The Challenge:

The required compensation power of 900kVAr with the possibility of its gradation (2 x 450kVAr) and very limited space for installation compared to standard solutions.

The Solution:

A unique solution designed specifically for the Partner's needs, with two independent reactors placed one above the other. Reactors of this type are usually used in wind farms to compensate the reactive power resulting from the capacity of the supply lines.

Results:

The compensation reactor type ED3KH-2x450 is one of two double compensation reactors with a power of 900kVAr (2x450kVAr) and a rated voltage of 15.75kV. ED3KH-2x series reactors have a common yoke, which reduces the amount of materials used for their construction (compared to two separate, independent reactors), giving economic benefits and making the most of the available space.

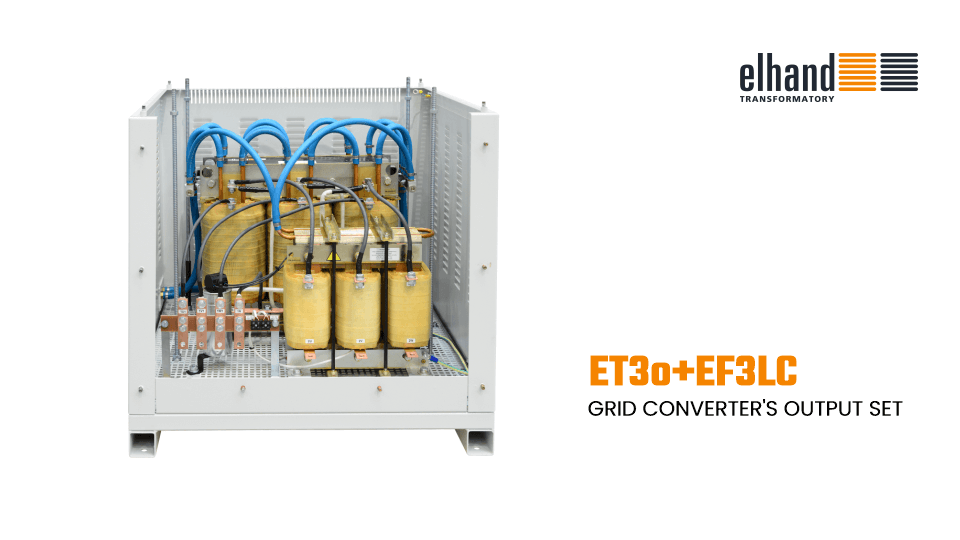

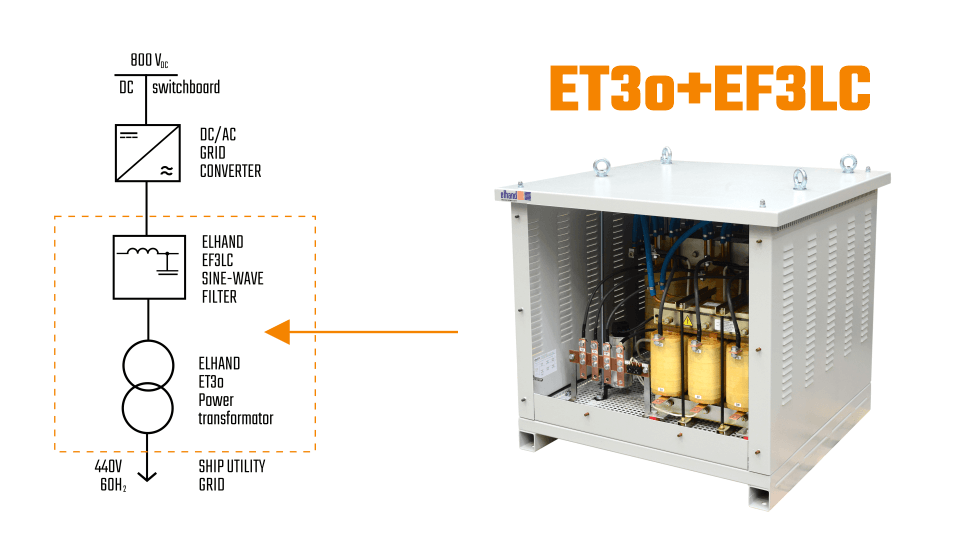

Grid Converter's Output Set

Reliability of the solution, high performance, minimum weight and dimensions

- Клиент Praxis Automation Technology B.V.

- Отрасль Морская отрасль

- Категория

Трансформаторы,

Фильтры - Дата Май 20, 2022

Client:

Praxis Automation Technology B.V. develops and manufactures ship automation and electric propulsion systems for all types of vessels. With all applied products of the automation and electric propulsion systems developed and manufactured in-house, Praxis offers a unique package which requires little to no system integration work. This approach is unique on the market and ensures unsurpassed cost efficiency and safety.

The Challenge:

Praxis is a leader in supplying electrical systems for fast motor yachts. Market trend is to minimize the weight and dimensions of all ship equipment. That forces the manufacturers to look for the most optimized solutions. Products need to be small and light, while keeping top performance and high reliability.

The Solution:

Elhand offered individual, compact design of an LC filter and a transformer in a common enclosure. To reduce the weight, both the windings and the enclosure were made of aluminum. The other goal was to minimize the footprint, which was achieved by implementation of a water cooling system. The customer received a dedicated product, which was easy to integrate with the yacht’s electrical system.

Results:

GRID CONVERTER'S OUTPUT SET is a ready-made solution, which enables connection of a grid converter to the ship utility grid. Frequency converter’s output voltage is transformed from PWM to sinusoidal waveform thanks to the sine-wave LC filter. Then the transformer eliminates common-mode voltage and adjusts its value to the customer’s requirements. The grid converter together with Elhand components create sinusoidal, galvanically isolated and stable voltage supply.

Трансформаторы 125 кВА-1600 кВА

Тяжелые условия окружающей среды, необычные электрические условия, оптимизация тепловых потерь.

- Клиент LOTOS Petrobaltic

- Отрасль Добыча нефти и газа

- Категория Трансформаторы

- Дата Февраль 15, 2022

Клиент:

LOTOS Petrobaltic, , единственная польская горнодобывающая компания, занимающаяся разведкой и добычей нефти и газа на польском шельфе Балтийского моря, а также комплексными оффшорными логистическими услугами, морскими исследованиями и управлением флотом.

Задача:

- Проектировка трансформаторов с разными степенями защиты IP, соответствующих высоким стандартам безопасности для нефтяных платформ, работающих в тяжелых условиях окружающей среды.

- Хорошие результаты испытаний требуемых морским классификационным обществом PRS.

- В дополнение к необычным электрическим условиям инвестор ожидал оптимизации тепловых потерь, а также использования и приспособления конструкции к требуемым размерам.

- Разнообразные виды транспортировки и очель сложный способ монтажа в небольших помещениях.

Решение:

Индывидуальные и прототипные проекты. Высокие и тонкие, низкие и широкие трансформаторы, хорошо работающие в тяжелых условиях окружающей среды. Планирование и реализация всего логистического процесса, обеспечивающего эффективную и безопасную поставку и сборку трансформаторов в небольших помещениях на модернизированной нефтяной платформе.

Результаты:

За последние 2 года в связи с модернизацией платформы Lotos Petrobaltic мы произвели богатую и разнообразную серию трансформаторов среднего и низкого напряжения мощностью от 125 кВА до 1600 кВА.

Трансформаторы и дроссели

Работа в тяжелых условиях окружающей среды, сильные токи, размер и компактность решения.

- Клиент Enika

- Отрасль Железнодорожная отрасль

- Категория

Трансформаторы,

Дроссели - Дата Январь 17, 2022

Клиент:

ENIKA Sp. z o. o. с 1992 года занимается проектированием, производством и сервисным обслуживанием устпойств силовой электроники для железнодорожного подвижного состава, трамваев, троллейбусов, электробусов и промышленности.

Задача:

Производители магнитных устройств в железнодорожной промышленности сталкиваются с многими задачами. Это не только работа в тяжелых условиях (при высокой степени загрязнения, повышенной влажности и конденсации, постоянном риске повреждения механики, сильных токах (подстанции)), часто также важны размеры и компактность данного решения.

Решение:

Трансформаторы и дроссели производства ELHAND Transformatory предезначены для работы в среднечастотных цепях железнодорожных преобразователей, по сравнению со стандартными решениями, характеризуются меньшими габаритами, благодаря чему конечное устпойство при их использовании может стать более компактным..

Результаты:

Многолетнее сотрудничество по поставке магнитных элементов: трансформаторов и дросселей.

Рекомендации:

"Устройства производства Elhand Transformatory Sp. z o.o. используются в устройствах силовой электроники, которые мы производим для железнодорожного подвижного состава, троллейбусов, электробусов и промышленности.

Используемые нами устройства производства Elhand Transformatory Sp. z o.o. работают безотказно и не вызывают никаких проблем в эксплуатации.

Трансформаторы и дроссели, поставляемые компанией Elhand Transformatory Sp. z o.o., изготовлены с максимальной осмотрительностью."

Bartosz Szyller

Заместитель президента, Enika Sp. z o.o.